Carbon aerogel based single cell for supercapacitor development (100V, 10 kJ) |

Quick View Leaflet

Supercapacitor (SC) is an efficient energy storage device having high capacitance in the range of hundreds of farads. SC possess various advantages over conventional storage device like batteries such that longer cycle life, faster charge discharge rates, lower equivalent series resistance and wider operating temperature range. Carbon aerogel (CA) based single SC cells have been fabricated and tested at PMTS, RRCAT. A large number of such individual SC cells were used for fabrication of supercapacitor modules of ~12 V (36 cells) and~100 V (142 cells). Mesoporous CA having surface area of ~875 m2/g prepared by freeze drying technique was used as electrode materials for SC fabrication. Cells are clubbed together in series to increase the voltage. This module haspotential for replacement of energy storage capacitors by these high energy supercapacitors required for ongoing projects in DAE units.

Detail Technical Brochure

Supercapacitor works on the principle of electric double layer formation at the interface of electrode and electrolyte. Manifold capacitance enhancement in SC than normal capacitors is achieved due to large interface provided by high surface area carbon materials and very small separation distance of electric double layer.

1. Fabrication of supercapacitor module: Fabrication involves preparation of carbon aerogel, electrode preparation and cell fabrication described below:

1.1 Carbon aerogel preparation:

Mesoporous carbon aerogel (CA) synthesized by freeze drying technique by using resorcinol-formaldehyde as the main precursors is used as electrode materials for the supercapacitor. Total surface area and mesopore surface area of freeze dried carbon aerogel is more than ~875 m2/g and ~350 m2/g respectively evaluated by N2 gas adsorption technique using surface area analyzer. Carbon aerogel is grinded in vibratory cup mill and sieved to <50 micron particles.

1.2 SC module fabrication:

The slurry of carbon aerogel is prepared using 3% aqueous KOH electrolyte and pasted on flexible carbon conducting sheet to prepare an electrode using semiautomatic prismatic cell assembly line. Repeating this process, multiple electrodes are prepared. A single supercapacitor cell is formed by placing two electrodes in parallel manner with cellulose paper as separator. Several such single cells are then assembled together in series / parallel to achieve the desired voltage. Connections are taken using copper foil and connected together to make electrical terminals. Complete assembly is enclosed in an epoxy cover to form supercapacitor modules of 12 V (36 cells) and 100 V (142 cells).

1.3 Testing of SC module:

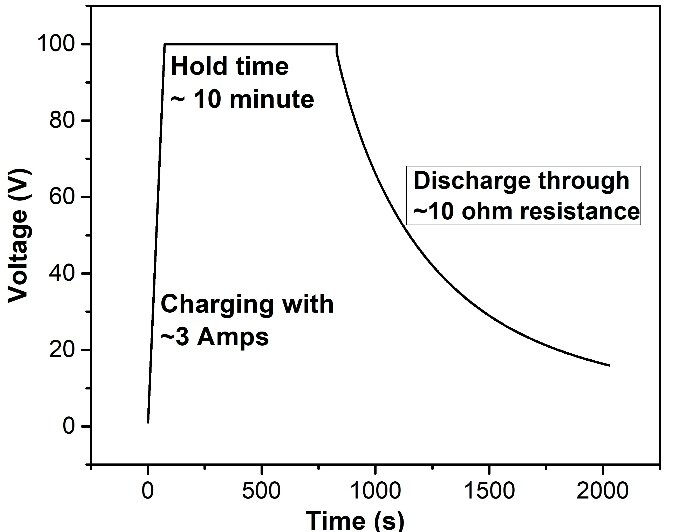

FD-CA based ~100 volt supercapacitor module was fabricated by such technique and performance testing of this module was carried out as per international testing standards (IEC/EN 62391). Capacitance of CA-SC module is measured by constant resistance (~10 Ω coil resistor) discharge method shown in figure 1.

Figure 1. Charge discharge profile of the fabricated SC module

- Technical Specification of SC Module

|

S. No. |

Description |

Value |

|

a. |

Capacitance (farads) |

~2 F |

|

b. |

Voltage (volt) |

~100 V |

|

c. |

ESR (m Ω) |

~ 150 m Ω |

|

d. |

Total energy stored (kilo-Joule) |

~ 10 kJ |

|

e. |

Physical dimension (mm) |

170x150x230 mm |

2. Typical End Applications:

- Alternative of energy storage capacitor (ESC) for higher energy densities storage

- For substitution of inline capacitor bank of Laser power supplies.

- Regenerative braking system for hybrid vehicles

- For grid stabilization in renewable energy (Wind, Solar) sources

- For cranking of heavy military vehicles in freezing temperature hilly terrain

3. Applications specific to DAE:

- Alternative to energy storage capacitor (ESC) for higher energy densities in DAE units

- For substitution of inline capacitor bank of Laser power supplies.

4. Facilities Required for Commercial Production

- Floor Space (at least 100 sq m) required for fabrication of CA based supercapacitor

- Vibratory cup mill & sieve shaker for fine CA powder, Prismatic cell assembly line for electrode preparation, Hydraulic press & Supercapacitor testing setup

- Utilities like slurry mixer, tab welding, epoxy molder and electrical power.

5. Manpower Requirement

- One graduate (B.Tech. Electrical) having at least two years experience in working similar field and

- one technician (plant operator) with two years of experience in similar field are sufficient to start production.