Agni Rakshak - Raman optical fiber based distributed fire sensor system |

Overview

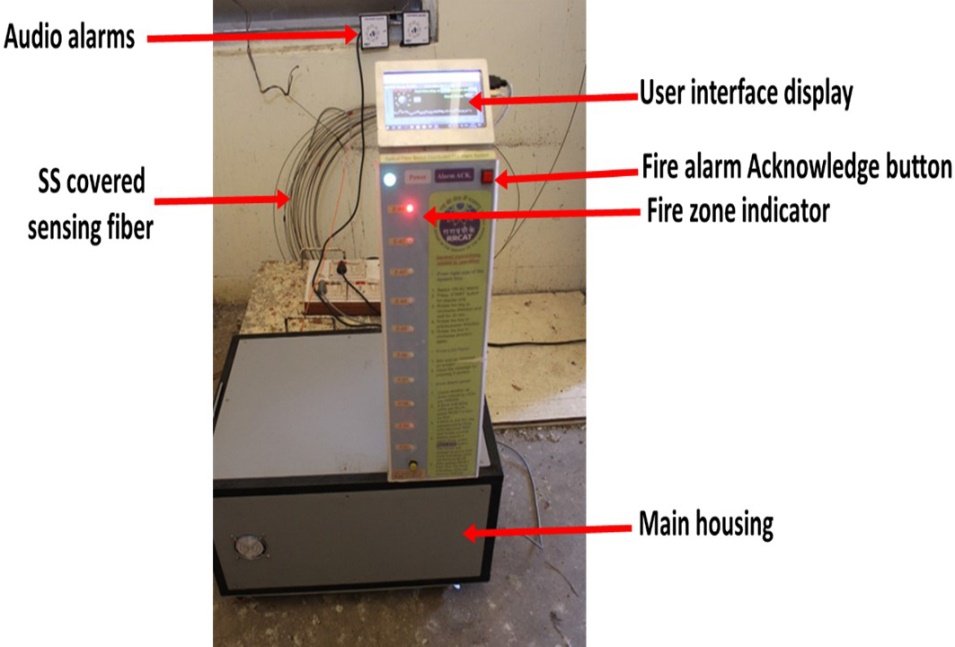

'Agni-Rakshak' is a Raman optical fiber distributed temperature sensor system that can detect distributed and local fire events over long lengths. It basically measures the distributed temperature over long lengths (up to few hundred meters or more) along the sensing fiber. Here, the optical fiber itself acts as an array of distributed sensing elements. The system is very useful in detecting the onset of fire by sensing the heat. It has the capability to provide the information about the location, width and temperature of the fire zone to which the sensing fiber is subjected to. The system can generate the audio-visual alarms for various fire zones in the fiber. 'Agni-Rakshak' has its applications in fire monitoring in hospitals, buildings, road & rail tunnels, stations, cable trays of power cables, high capacity transformers, coal conveyors, warehouse and storage, cement industry, oil & gas Industry, Nuclear industry and sensitive installations etc.

Quick View Leaflet

Agni-Rakshak is a Raman optical fiber based distributed temperature sensor (DTS) system that measures distributed temperature over long lengths (up to few hundred meters or more). Here, the optical fiber itself acts as an array of distributed sensing elements. The system is very useful in detecting the onset of fire by sensing the heat. It has the capability to provide the information about the location, width and temperature of the fire zone to which the sensing fiber is subjected to. The system can generate the audio-visual alarms for various fire zones in the fiber. The alarm temperature can be programmed by the user. 'Agni-Rakshak' has its applications in fire monitoring in hospitals, buildings, road & rail tunnels, stations, cable trays of power cables, high capacity transformers, coal conveyors, warehouse and storage, cement industry, oil & gas Industry, Nuclear industry and sensitive installations etc.

'Agni-Rakshak' has hassle free installation and operation. No complex wiring of numerous point sensors is required as it uses single fiber optic sensing cable. Since 'Agni-Rakshak' uses optical fiber as sensing element which is passive in nature, there is no hazard of fire due to spark in areas dealing with inflammable material like coal, gasoline, diesel etc. It works well in harsh environments such as high EMI, hazardous radiation etc. All the necessary technical support with the available resources will be provided to the industries obtaining the technology transfer of 'Agni-Rakshak'. However, it is the responsibility of the concerned industry to take the necessary approval from the respective approving agency for the deployment of sensor as per application specific requirement.

ADVANTAGES

- Ability to react to distributed and local fire events for rapid action and effective troubleshooting.

- Single sensor is able to detect fire over a wide spread area.

- Provides information about the onset of fire well before the actual fire takes place.

- Hassle free installation, no complex wiring of numerous point sensors. Based on single fiber optic sensing cable. No individual sensors are required.

- Uses optical fiber as passive sensing element, no hazard of fire due to spark in areas dealing with inflammable material like coal, gasoline, diesel etc.

- Effective even in harsh environments of high EMI.

APPLICATIONS

Fire Monitoring in

- Hospitals

- Buildings Storage tanks

- Road and rail tunnels and stations

- Cable trays of power cables

- Transformers

- Coal conveyors

- Warehousing and Storage

- Cement Industry

- Oil and gas Industry

- Nuclear Industry

- Sensitive installations

Detail Technical Brochure

TECHNICAL SPECIFICATIONS

| Sr. No. | Specification | Value |

| 1 | (i) Optical fiber sensor type | (a) SS seamless tube (1.8 mm) covered 62.5 µm /125 µm Multimode optical fiber OR (b) SS spiral tube (1.8 mm) with Aramid Yarn, low smoke zero halogen (LSZH) sheath covered 62.5 µm /125 µm Multimode optical fiber |

| (ii) Optical fiber loss | < 1.5 dB/km @ 1300 nm | |

| 2 | Channels | 1 |

| 3 | Temperature range | 25 – 300 °C |

| 4 | Typical sensor length | 200 m |

| 5 | Temperature resolution | 4 °C |

| 6 | Spatial resolution | 2 m |

| 7 | Sampling over fiber length | every 30 cm |

| 8 | Measurement time | 30 s (optimized for fire detection) |

| 9 | Alarm types | On crossing the maximum zone temperature |

| 10 | Zone wise alarm temperature | User programmable on fire |

| 11 | Switches | Power on/off, Optics power control on/off, Fire alarm reset |

| 12 | Indicators | Zone wise fire alarm indicators |

| 13 | Data storage | 4 GB |

| 14 | Size | (i) Main housing: 70 cm × 50 cm × 43 cm (ii) With display unit: 70 cm × 50 cm × 113 cm |

| 15 | Electrical input | 220 V AC, 5 A, single phase |

| 16 | Weight | 30 kg |

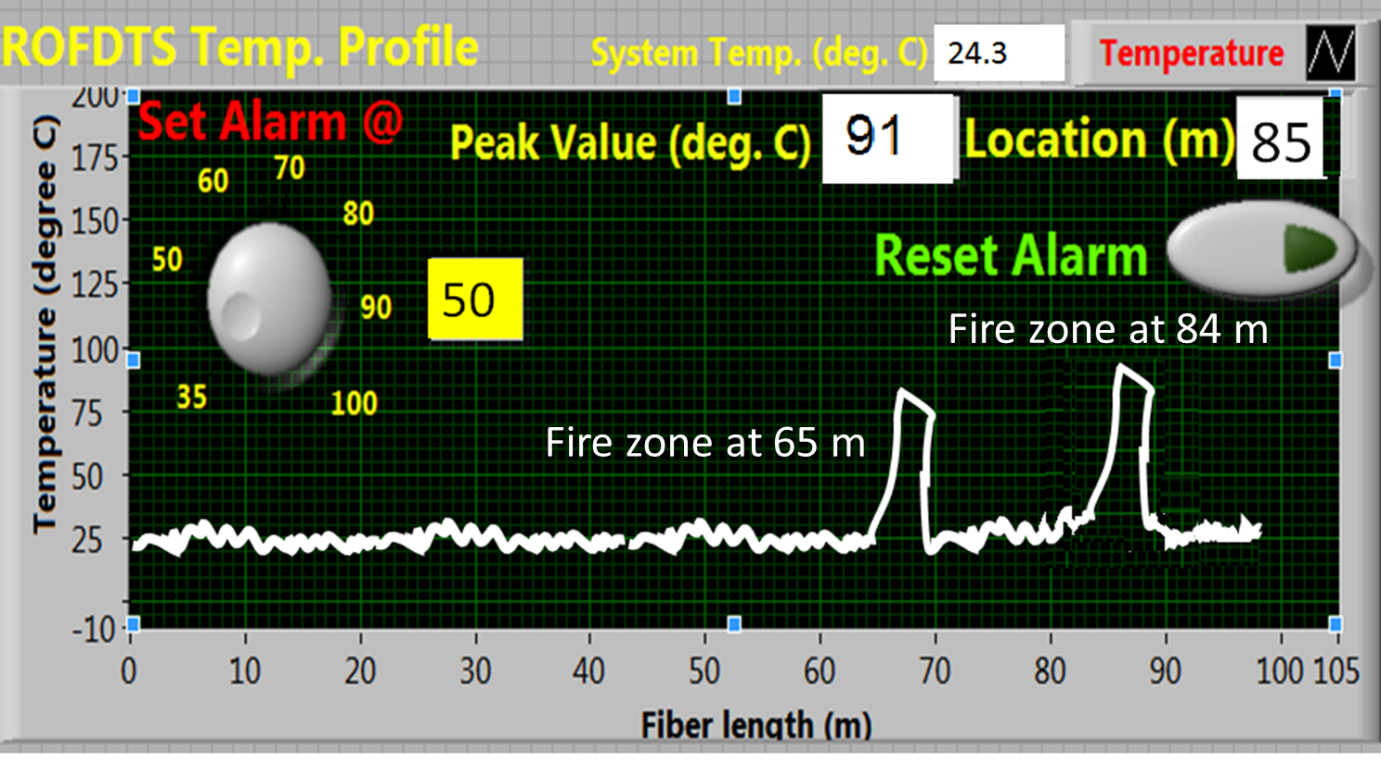

PERFORMANCE/RESULTS OF FIRE DETECTION BY AGNI-RAKSHAK

The details of the tests conducted and the results obtained are given below

- The fire was lit at the location of 68 m in 2 m long zone at a gap of 20 cm from the sensing fiber using 200 ml chafing fuel. The fire was detected within 30 s.

- The fire was lit at the location of 50 m in 10 cm long zone at a gap of 1 cm from the sensing fiber using two A4 size papers. The fire was detected within 45 s.

- The fire was lit at the location of 80 m in 1.5 m long zone at a gap of 50 cm from the sensing fiber using 200 ml chafing fuel. The fire was detected within 50 s.

- The results were found to be reproducible.

FACILITIES REQUIRED FOR COMMERCIAL PRODUCTION

Following are the details of the facilities required for commercial production of 'Agni-Rakshak' instrument.

- Floor area

- Electrical supply

- Workshop facilities required

- Man power

1. Floor area

- A floor area of minimum size of 20 ft (l) × 40 ft (w) × 12 ft (h) is required to start the commercial production of 'Agni-Rakshak' instrument. The area must have at least four working tables of size 4 ft × 8 ft.

2. Electrical connection

- The workshop that will be used for commercial production of 'Agni-Rakshak' instrument must have an electrical connection of 1 kW power with 220 V AC, 5 A, single phase electrical distribution box connections on each table.

3. Workshop facilities required

- The workshop should be equipped with bench vice, electrical drill machines and basic machining/fitting too kit.

- The basic facilities related to optics like power meter, optical fiber splicer, infra-red laser viewing cards etc. must be available in the workshop.

- The basic facilities related to electronics like digital multi meter, digital storage oscilloscope, soldering iron, wire cutter, wire stripper etc. must be available in the workshop.

- The workshop should have a basic paint shop facility with scrubber, paint gain and heater. Although, these facilities can also be outsourced.

4. Man power

A minimum of four persons with following educational qualifications are required to start the commercial production of 'Agni-Rakshak' instrument.

A. Engineering In charge (01)

- The candidate for the post of Engineering In charge must have B.E./B.Tech. degree in Electronics/Instrumentation Engineering or M.Tech./M.Sc. degree in Optoelectronics with basic knowledge of programming languages like LabVIEW and embedded C. An experience of 3 years in the field of optoelectronic circuits and Arduino microcontrollers is desirable.

B. Technicians

Fitter (01)

- The Fitter must have ITI certificate in Fitter Trade with 2 years of work experience in the field of fabrication of instrument cases.

Electronics (01)

- He must have ITI certificate in Electronics Trade with 2 years of work experience in the field wiring of electronic instruments and PCB soldering.

- The Electronic Technician can have either diploma in Electronics/Electrical/Instrumentation Engineering or ITI certificate in Electronics/Electrical/Instrumentation with experience in production of optoelectronic instruments.