10 MeV 15 kW Industrial Electron Linac Technology (KIRTI1015) |

Quick View Leaflet

RRCAT has developed lab scale prototype of high energy, high power (10 MeV, 15 kW) linacs for food irradiation and sterilization of medical devices. This technology is also useful for other applications like radiotherapy, industrial radiography of thick components, neutron radiography, cargo scanning, and strategic applications with suitable modifications. Linac manufacturing involves multiple domain knowledge in e-gun, RF, pulsed systems, magnetics, beam delivery system, controls, vacuum, etc.

Detail Technical Brochure

Detailed Technical Brochure

Preamble: RRCAT has developed lab scale prototype of high energy, high power (10 MeV, 15 kW) linacs for food irradiation and sterilization of medical devices. This technology is also useful for other applications like industrial radiography of thick components, neutron radiography, cargo scanning, radiotherapy and strategic applications with suitable modifications. Linac manufacturing involves multiple domain knowledge in e-gun, RF, pulsed systems, magnetics, beam delivery system, controls, vacuum, etc.

|

|

10 MeV, 15 kW Linac assembly |

1.0 TECHNICAL SPECIFICATIONS

Electron Linac for radiation processing applications with following specifications.

|

S.N. |

Specification |

Value |

|

1. |

Nominal beam Energy |

10 MeV |

|

2. |

Nominal Beam current (Pulse) |

400 mA |

|

3. |

Beam pulse duration (95% value) |

14 µs |

|

4. |

Nominal beam power |

15 kW |

|

5. |

Energy spread |

≤ ±5% |

|

6. |

Maximum Beam size |

~25 mm on beam window |

|

7. |

Scan width |

600-1000 mm on beam window |

|

8. |

Dose uniformity on product surface (~30 cm from beam window) |

± 10% |

2.0 PERFORMANCE OF LINAC

The details of the tests conducted and the results obtained are given below.

|

|

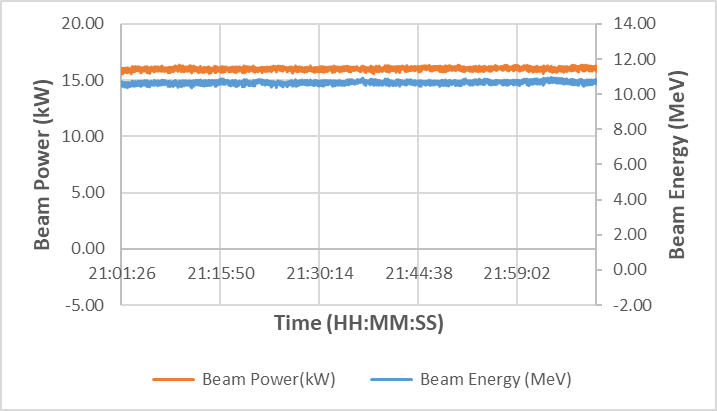

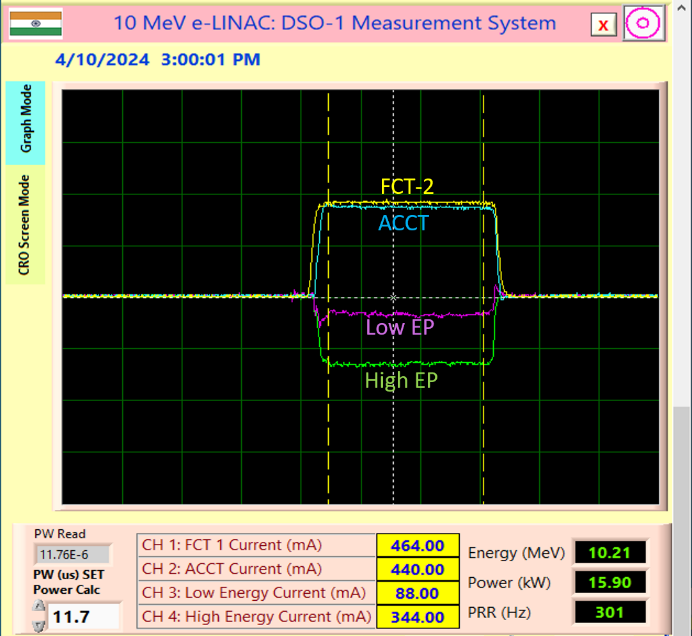

Beam parameters stability during Linac operation |

|

|

Beam parameters during Linac operation |

3.0 FACILITIES REQUIRED FOR COMMERCIAL PRODUCTION

Following are the typical facilities required for commercial production of '10 MeV industrial Linac:

|

S.N. |

Facility description |

|

1. |

Understanding/ knowledge/ expertise in power electronics/ pulsed power electronics/ RF Engineering |

|

2. |

Power electronics assembly capabilities (inverter /converter and HV modules with voltage range of 40 kV). |

|

3. |

Switchgear, switch connector, contactor assembly capabilities for 3-phase, 415 V, 120 kVA ratings. |

|

4. |

HV, oil immersed, pulse transformer manufacturing capabilities for 140 kV, 120 A delivery with dehumidifier. |

|

5. |

Coil winding, Dry transformer windings in power rectifier (16 kV, 100 kVA), isolation transformer (isolation voltage 150 kV, power handling 500 VA) with vacuum impregnation. |

|

6. |

High voltage probes, Digital signal oscilloscopes, RF power meter, multimeter, RF measurement instruments like VNA with calibration kit and RF cables |

|

7. |

Machining and inspection facility: CNC lathes & milling machines for Precision turning to a diameter of 150 mm having tolerances of ±5 micrometer. Milling capabilities with sizes 150 mm having tolerances of ±10 micrometer. CMM & Surface roughness measurement. |

|

8. |

Chemical facility: Chemical cleaning & electroplating |

|

9. |

Vacuum brazing facility: Brazing furnaces 900°C |

|

10. |

Vacuum hardware: Pumps, Leak detectors and instrumentation |

|

11. |

Assembly area: Dust controlled clean area of size 10m x10m x 3m Dry and epoxy floored assembly rooms with filtered air supply, dust control curtains. |

|

12. |

Low conductivity water chiller plant: 300 LPM at 26 ± 1 °C |

|

13. |

Deep bore electrical earthing with resistance less than 1 ohm |

|

14. |

Electrical power: 3 Phase, 150 kVA |

4.0 MANPOWER

Minimum manpower required for manufacturing and assembly of Linac is given in Table below.

|

S.N. |

Qualification |

Number |

|

1. |

M. Tech in power electronics/ RF |

One |

|

2. |

B. Tech/ M. Tech in Engineering Physics |

One |

|

3. |

B. Tech/ M. Tech in Mechanical Engineering |

One |

|

4. |

Diploma in Electronics/ Electrical Engg. |

One |

|

5. |

Diploma in Mechanical Engg |

One |

|

6. |

ITI Fitter in Electronics/ Electrical Engg. |

Two |

|

7. |

ITI Fitter in Mechanical/ Electrical Engg. |

Two |

|

8. |

ITI Draftsman |

Two |